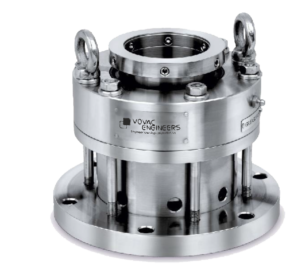

AGITATOR MECHANICAL SEAL

Build strategies, build confidence, build your business.

The bearing of the seal face is responsible for safeguarding and enabling seamless motion.

S.S RECTOR (VDS 11 & VDS 11/1)

Seal Type VDS-11 AND VDS-11/1 Mechanical Seals Are Designed For Top, Side And Bottom Entry Drives In Agitators And Reactors. Compact Economical Cartridge Double Mechanical Seal For Agitators And Reactors.

- Sealing Environment

- Excellent With Low RPM Operation

- High Speed for Operation in Vacuum Conditions

- Design May Use Either Without Bearing OR With Integral Bearing.

- The Cooling Chamber is Provided for Better Cooling Environment to The Seal.

HYDROGENATOR VDS 13

Seal VDS-13 Mechanical Seals Are Designed For Top Entry Drives In Hydrogenators. Seal VDS-13 Design Incorporate With Location Of Bearing Very Close To The Seal. These Seal Specially Designed For Any Mixed And Pressurized Liquid In Vessel With Top Entry Agitators Where No Leakage In Process Gas OR Fluids To The Environment Can Be Tolerated.

- Sealing Environment

- The Design with Integral Bearing

- Various ElastomerCan Be Offer for Various Liquid Application.

- Double Seals Are Excellent with Low RPM Operations in Full Vacuum Pressure.

- The Cooling Chamber Is Provided for Better Cooling Environment to The Seal.

GLASS LINED REACTOR VDS 15 & VDS 15/1

Seal Type VDS-15 & VDS-15/1 Mechanical Seal Are Designed For Top Entry Drives In Glass Lined Vessel. Compact Economical Cartridge Mechanical Seal For Glass Lined. These Seal Specially Designed For Any Mixed And Pressurized Liquid In Vessel With Top Entry Agitators Where No Leakage In Highly In Acidic Process Gas OR Fluids To Be Environment Can Be Tolerated.

- Give Better Performance in Sealing Environment.

- The Design Without Bearing For VDS-15.

- Use Integral Bearing in VDS -15/1.

- Cooling Jackets Provide for Ensure Cool Running of Seals.

DOUBLE SEAL FOR BOTTOM ENTRY VDS 14

Seal Type VDS -14 & VDS 14/1 Mechanical Seal Are Designed For Bottom And Side Entry Drives In Rectors. Compact Economical Cartridge Double Mechanical Seal. The Design May Either Without Bearing (VDS 14) Or With Integral Bearing (VDS 14/1). Complete Pre – Assembled Tested Unit Ready For Installation.

- Balance Pusher Seals Using For Environment.

- Low RPM Operation In Full Vacuum And Pressure.

- Liquid Application.

- Maintain cool Environment around the seal

DRY RUNNING SEAL FOR HIGH SPEED VDR 21

Seal Type VDR-21 Mechanical Seal Are Designed For Top, Bottom And Side Entry Drive In Agitators, Mixers OR Blenders In Case When Non- Aggressive And Non- Hazardous Media Are Sealed With The Use Of Colling Liquid Preventing Against Dry Running. Construction Of MOC Designed Of These Seal Purpose Of Holding Whole Rotary Parts Together With The Help Rings Which Make Easy For Installation And Removal.

- Easy Installation and Removal

- Sealing Environment

- High Speed in Undemanding Mixer Application as Well as Vacuum.

- Use Mating Ring for Dissipate the Heat from Faces.

- Integral Bearing

- Various Elastomer Can Be Offered for Various Media Application.

Have You Any Question Or Query?

GET FREE CONSULTATION WITH OUR AGENT